Product Description

Applicable Industries:Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Farms, Construction works, Energy &Mining

Place of Origin: Fujian, China

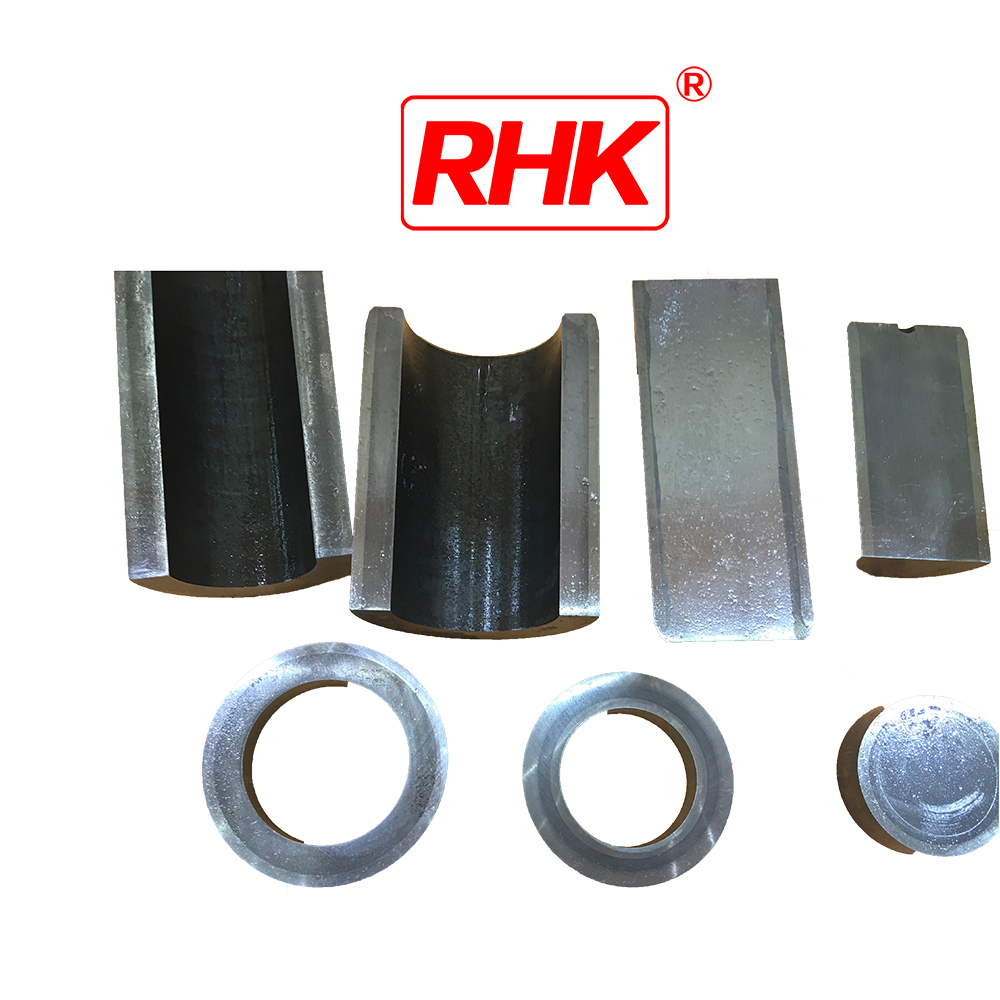

Product Name : TRACK PIN AND BUSHING

Brand Name:

Model:

Condition: New

Packing: Wooden case, Pallet

Material: Alloy Steel or Steel

Warranty: 2 Years

Sample: Available

Size: Standard

Color: Customer’s Request

Logo: Customer’s Request

Marketing Type: New Product 2021

Technical: Forging and Casting

Certification: ISO9001:2015

Payment terms:T/T

OEM:Avaliable

MOQ: 20pcs

Supply Ability

Supply Ability: 50000 Pieces / Month

Packaging & Delivery

Packaging Details: in wooden case or fumigate pallet

Port: Xiamen Port