When it comes to purchasing high quality bucket pin, exactly it is for excavator undercarriage. Particularly, it is essential to choose a reliable excavator parts supplier. Choosing a trusted excavator undercarriage manufacturer is important. Because it guarantees that you will get quality parts that will last a long time. Additionally, buying a high quality bucket pin can lead to numerous benefits. Such as increased efficiency, improved performance, and lower maintenance costs. It is also important to ensure that you are getting a good deal when it comes to excavator undercarriage. As this can have a significant impact on the longevity and overall cost of the parts.

Excavators are heavy-duty machines that are used for construction, mining, etc. These machines have various parts that work together to accomplish a specific task. One of the most crucial parts of an excavator is the bucket pin. In this post, we will explore what bucket pins are, their types. And how they work?

Whether You Know What Bucket Pins Are

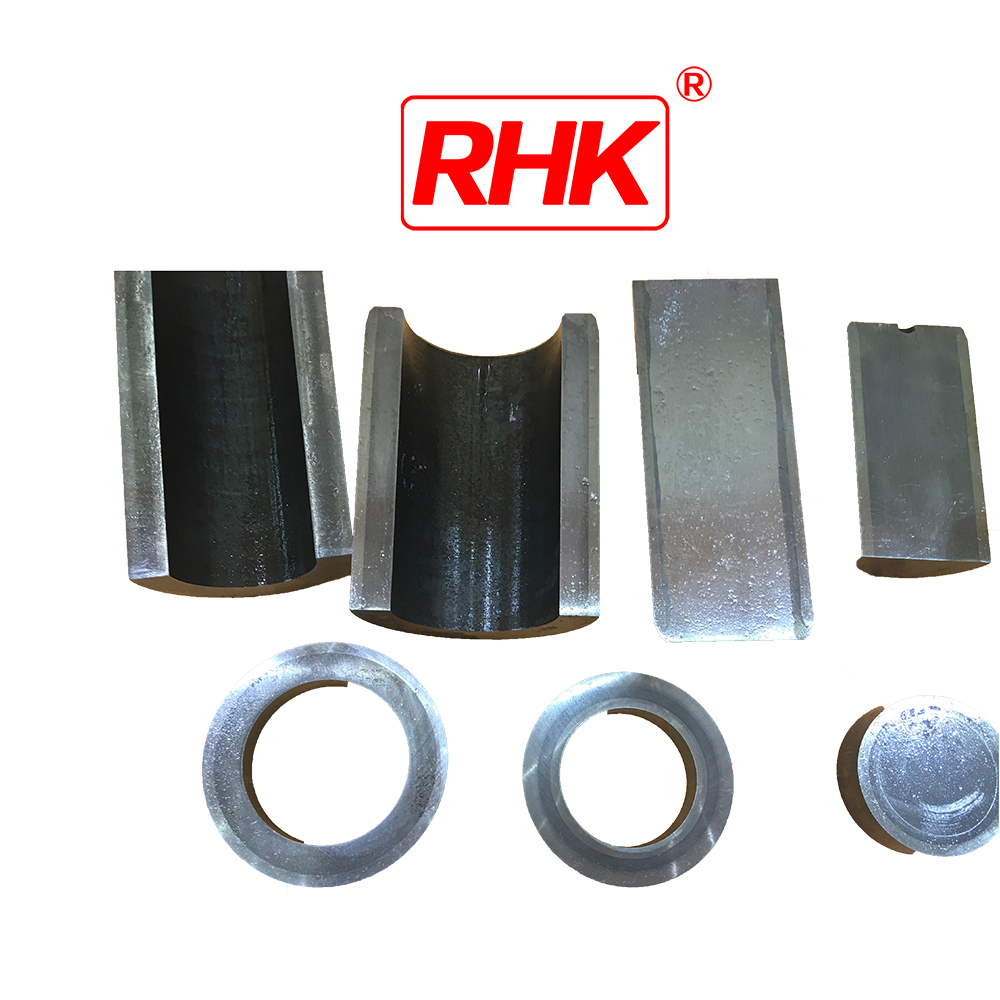

Bucket pins are a type of pin that connect the excavator’s bucket to the machine’s arm. These pins allow the bucket to pivot and rotate. At the same time, enabling the excavator operator to perform different tasks. These tasks are such as digging, scooping, and moving materials. The bucket pin from excavator undercarriage manufacturer, is one of the most critical components of an excavator. As it bears the weight of the bucket and the materials it carries.

Top 5 Types Of Bucket Pins

- Bucket pins, from excavator parts supplier, come in various types. It depends on the type of excavator and the specific task it is used for. Here are some of the most common types of bucket pins:

- Straight pins: Straight pins are the most common type of bucket pin and are used in most excavators. They are cylindrical in shape and have a smooth surface.

- Greased pins: Greased pins are designed with a small hole that allows grease to pass through them. They are used in excavators that require continuous lubrication.

- Hardened pins: Hardened pins are made of hardened steel and are designed to withstand extreme pressure and wear. They are commonly used in heavy-duty excavators that work in harsh conditions.

- Split pins: Split pins have a split design and are used in excavators that require frequent disassembly and assembly of the bucket.

Tell Buyers About How Bucket Pins Work?

Bucket pins by excavator parts supplier, work by connecting the excavator’s bucket to its arm. When the excavator’s arm moves, the bucket pins pivot and rotate. It allows the bucket to move in different directions. The bucket pins are held in place by retaining rings, which prevent them from falling out of their sockets.

Maintenance Of Bucket Pins Is Important Thing

Maintaining bucket pins is critical to keeping your excavator working efficiently and safely. Bucket pins by excavator undercarriage manufacturer, must be checked and lubricated regularly to prevent wear. If the bucket pin is damaged or worn, it should be replaced immediately to avoid accidents.